Cenicaña and the mills collected information about the technologies adopted by sugarcane producers on farms in the Cauca River Valley.

Between April 2013 and June 2014, as part of the Learning and Technical Assistance Program (PAT), Cenicaña, with the support of the sugar mills, collected information to find out the level of technology adoption in the sugar cane production units in the Cauca river valley.

A representative group of producers, made up of 396 cane suppliers (PV) and 39 area administrators on land with direct management of twelve mills (MD), answered the survey designed by Cenicaña. The results show the level of technology adoption before beginning the activities of the learning and technical assistance program; The twelve mills harvest 98% of the area cultivated by the agro-industry, a little more than 50% with the management of cane suppliers.

This baseline characterization is the benchmark for setting PAT goals. The training program with the cane growers is defined by each mill according to their capacity and following the activity plan agreed with Cenicaña; the Research Center provides them with the necessary support in the process.

Adoption level (April 2013-June 2014)

- Agronomic management of cane suppliers (PV)

- Direct management of mills (MD)

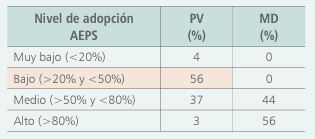

Specific agriculture per site, AEPS®

The level of adoption of AEPS is calculated based on the responses of each producer to a series of questions related to the usefulness of agroecological zoning (fourth approach) in making agronomic management decisions. Seven technologies (between varieties and cultivation practices) are taken into account, which are assigned a value of relative importance according to the humidity condition of the representative agro-ecological zone of each farm.

Percentage of producers who make agronomic management decisions with an AEPS approach®

- According to the answers given by 56% of the cane suppliers, it was determined that the level of adoption of the AEPS is low in this producer segment:

- 51% stated that they do not know which is the main agro-ecological zone present in the productive unit.

- 65% selected the variety for renovation without taking into account the agro-ecological zone.

- 71% decided the cultivation practices without considering the agro-ecological zone.

Water balance, prioritized BH v.4.0

Do you use the prioritized water balance system to schedule irrigation on the farm?

- 27% of cane suppliers use the prioritized water balance system to schedule irrigation in 42.5% of the area where this cultural work is carried out.

Administrative control of irrigation, CAR

Which of the following measurements and calculations do you perform when applying irrigation on the farm?

- It was determined that 55% of the suppliers and 100% of the mills' zone administrators carry out measurements and calculations for the administrative control of irrigation.

- 16% of cane suppliers measure the volume of water applied per hectare in each irrigation. In the lands with direct management of the mills, 90% of the zone administrators carry out this measurement.

In the survey that was carried out to calculate the adoption levels, the technologies related to: agroecological zoning were consulted; field design and adaptation; varieties, seedbeds and sowing; water management (irrigation and drainage); nutrition and fertilization; pest management (Diatraea spp. Y Aeneolamia varies) and information technologies.

“Having this information and a team of facilitators trained to promote the training of suppliers, farm managers and butlers are sufficient reasons to be encouraged to participate in the PAT training sessions that the mills are programming; This will lead us to adopt new technologies on farms, to be more innovative and productive, "says Camilo Isaacs, head of the Cenicaña Technical Cooperation and Technology Transfer Service.

During 2014, with Cenicaña's support, the sugar mills carried out 112 training events for the PAT in which sugarcane employees and growers participated (see testimonies).

During 2014, with Cenicaña's support, the sugar mills carried out 112 training events for the PAT in which sugarcane employees and growers participated (see testimonies). “As a company, we find all the activities that are being carried out with the PAT very interesting because they provide us with important tools to measure and improve work. Today we are applying almost everything we have seen because we have found the training to be functional, and thanks to coordination with ingenuity, we have been able to put the technical part into practice "

Marco Antonio Garcia

Marco Antonio Garcia

Sugar Cane Provider La Cabaña

“Among the new technologies in the sugar agribusiness, the site-specific agriculture approach is one of the most important. Thanks to the training I received on the subject, I will try to better locate the different varieties of cane in the renovations and I will take into account the recommendations, especially in fertilization and water management. That will translate into better productions, which is what we all hope ”

Alberto quintero

Alberto quintero

Sugar cane supplier Riopaila

ADVANCES 2014

Learning and Technical Assistance Program

Cenicaña produced five methodological guides with guidelines for facilitators, technical reference content and a series of practices and exercises specially designed to promote learning.

The PAT methodology proposes a shared learning cycle, which is based on knowledge management and the development of competences for the adoption of improved practices in the productive units of the agro-industry.

Between March and November 2014, Cenicaña held three motivational workshops and thirteen training events with the participation of the PAT facilitators, professionals associated with the Carmelita, Castilla, Incauca, La Cabaña, Manuelita, María Luisa, Mayagüez, and Pichichí sugar mills, Providencia, Riopaila, Risaralda and Sancarlos.

Four cane production technologies and one factory technology were the learning topics for this year. Cenicaña dedicated 250 hours of training with the facilitators of the mills, who then held 112 events in which the end users of the technologies participated.