Learnings, achievements and challenges of energy cogeneration in the Colombian sugarcane agroindustry.

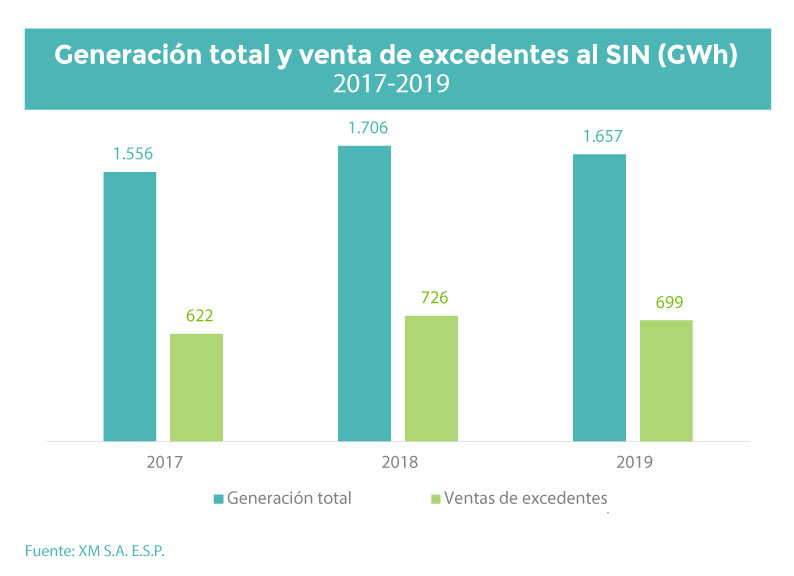

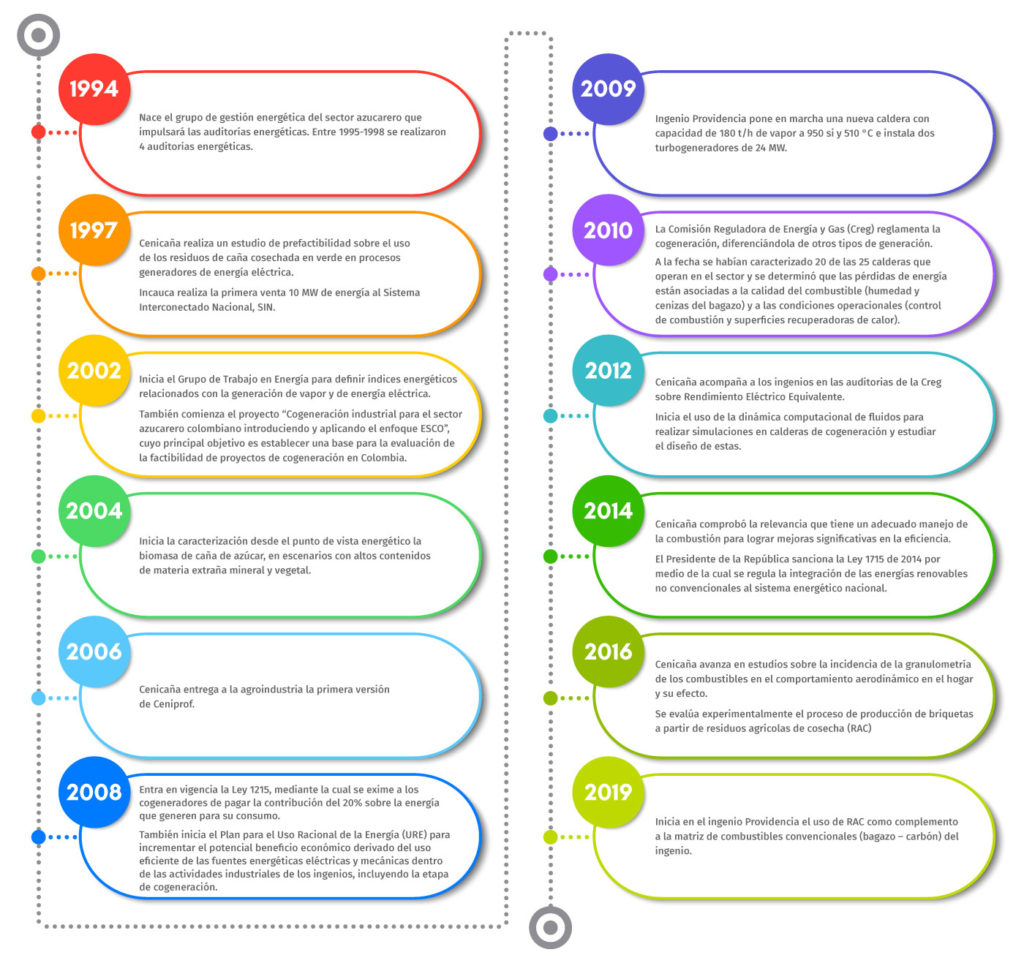

In 1997 Incauca made the first sale, contributing 10 MW of energy to the existing capacity in the National Interconnected System, SIN. Since then, the Colombian sugar cane agribusiness sees an opportunity for diversification in the energy market.

In fact, in 2019 eleven mills in the sector co-generated 1657 GWh of electrical energy - enough to meet the demand of a city of one million inhabitants - and sold 699 GWh.

Behind this increase in cogeneration and surpluses for sale to the national grid there is much more than a large amount of bagasse available. “This situation in Colombia is not alien to the global trend of using more and more renewable resources. The importance of energy cogeneration in the world and the projects to carry it out, have undergone significant development, and the causes of this change include the rise in fuel prices, the advance of the technology in renewable energies and the policies to reduce greenhouse gas (GHG) emissions that are reflected in the goals of the different countries ”, highlights Johan Martínez, director of the Renewable Energy and New Businesses area of Asocaña.

In this long journey, the experience, knowledge and technology of the sector have been fundamental, through the mills with the support of Cenicaña.

“In the nineties, when the Factory Processes program in Cenicaña began, it was thought of contributing to the energy cogeneration processes of the agribusiness and began with energy audits that would help determine the real situation of each mill in the generation, use and projections of energy ”, recalls Nicolás Gil, director of the Cenicaña Factory Process Program.

During this period, the need also arose to strengthen this experience with the knowledge of experts such as Peter Wright and Enrique Wittwer, experts on issues of energy use in factories.

The first contributions of the research to the cogeneration processes of the industry and that complemented what was achieved with the audits were tools such as Ceniprof, to predict operational performance in factories. "Energy audits help to identify opportunities and with Ceniprof it was allowed to analyze possible scenarios," says Julián Lucuara, Cenicaña's mechanical engineer.

But it was as of 2008, when Law 1215 came into force, which exempted cogenerators from paying the 20% contribution on the energy they generated for their consumption, that the mills saw an opportunity and increased their cogeneration capacity.

This situation motivated the mills to upgrade their cogeneration systems, replacing traditional low-pressure boilers (300 psig) with high-pressure boilers (950 psig) and acquiring higher-efficiency turbogenerators, in the search to increase surplus energy for the sale.

That is, it went from boilers with a pressure of 300 pounds of steam to 900 pounds and to turbo generators that from 25-35 pounds of steam generated one kW / h to equipment that only required between 9-12 pounds to generate the same amount of Energy.

As the mills expanded their capabilities, technical and knowledge needs arose that would allow them to improve processes, such as finding sources of energy losses. Cenicaña responded to these needs with the implementation of the standard to establish the thermal efficiency of the ASME PTC 4.1 boiler and the use of computational fluid dynamics to carry out simulations in cogeneration boilers and study their design.

With this latest tool, Cenicaña accompanied the La Cabaña mill in the design of its boiler and some of the contributions incorporated have contributed to reducing the consumption of tempering water and wear in the pipeline. At the Providencia sugar mill, problems with overheated steam were also corrected. According to Nicolás Gil, the cogeneration of energy by the mills brought with it a series of changes within the plants that are not limited only to boilers and turbogenerators with greater capacity or better technology. “In fact, the mill motors were not electric, they were not very efficient and less flexible for their control; With the technological renovation that promoted cogeneration, many internal processes could be electrified, hence the importance of addressing energy integration, an aspect in which Cenicaña has always been working ”.

Towards the future

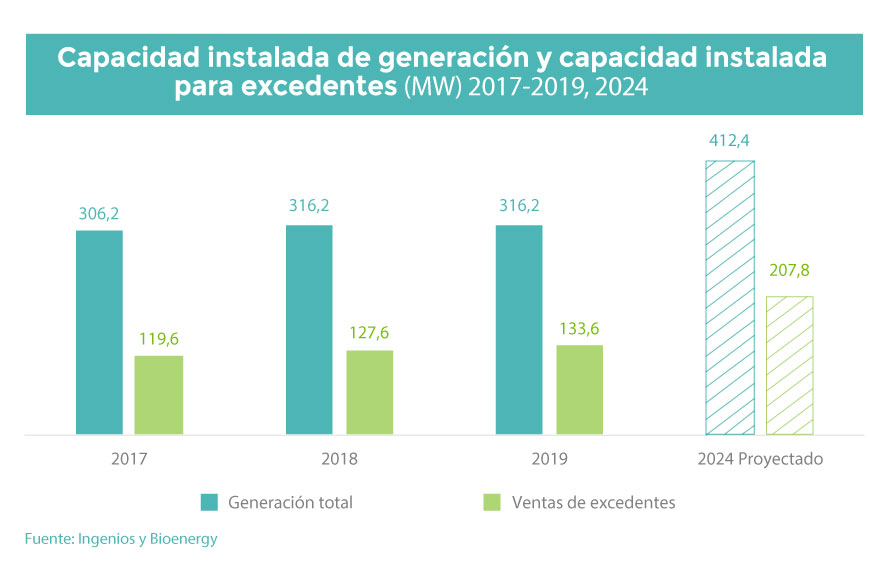

Asocaña projects that by 2024 the sector would be increasing its installed generation capacity by 30% and that of surplus sales by 56%.

Of course, reaching these projections depends on multiple factors and one of them is exploring the use of agricultural crop residues as an alternative to increase energy generation. The first steps in that direction are already being taken.

In Cenicaña, studies continue to improve boiler efficiencies and the sector is already making progress in incorporating RAC into its fuels, as in the case of the Providencia mill, which has been using it for a year and plans to gradually increase it to replace coal in its whole. Undoubtedly, these efforts and others that will come in the future will contribute to increasing this participation in the national energy matrix, which will lead not only to a more competitive sector, but to a more sustainable region.

A 'bioenergetic' region

Bioenergy is one of the strongest and most dynamic production chains in the region. The Bioenergy Cluster groups together the companies related to the processes of generating energy and fuels from the different biomass available in the geographic valley of the Cauca River (agricultural, forestry and livestock, among others).

Here more information.